Solar Power

Solar Power

For the House

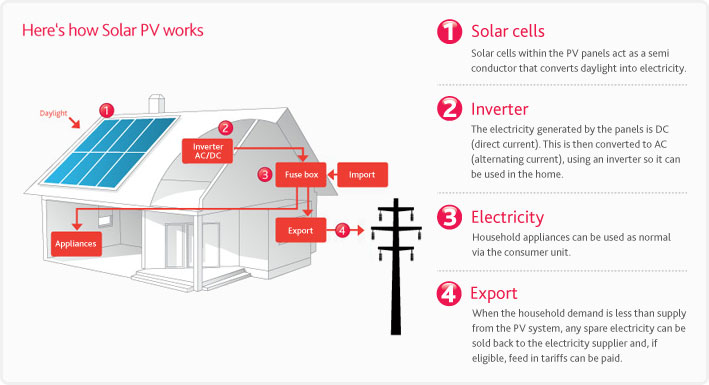

HOW DOES IT WORK?

Solar PV (Photovoltaic) technology has been around for a while and, put simply, converts sunlight into DC electricity that can be used in the home. The technical explanation on Solar PV is at the bottom of this page.

A household solar system, given you are using self-generated energy rather than energy from the network, is one of the most effective ways to reduce your energy bill.

HOW MUCH CAN I SAVE?

Solar systems can come in different sizes and should be professionally matched to your household energy profile. Household energy usage, the way and time that you use that energy, and the average amount of effective sunlight hours per day in your region will all contribute to the potential energy savings.

The best solution is to have a professional match a solar system to your electricity usage, hence maximising your energy saving and reducing your energy bill. Click here to obtain 3 free no obligation quotes.

HOW MUCH DOES IT COST?

Pricing is driven by a number of factors including the size of the system, quality of the components and the service the sales and Installation Company provides. There are also Government funded Incentive schemes currently available in some states which can subsidise the cost of the system. The details of the schemes are listed below but your sales and installation company will be the best people to advise your eligibility and potential rebate/discount/saving on your system cost.

GOVERNMENT INCENTIVES

Under the Federal Government’s Solar Credits Scheme eligible households receive money for small-scale technology certificates (STCs) created by their PV systems. STCs were formerly known as renewable energy certificates (RECs). The government uses these certificates as evidence of Australia’s contribution towards our renewable energy targets. When you are assessing your quote for a solar system be sure to consider the STC’s as part of the quote.

MORE INFORMATION

Photovoltaics

In 1839, French scientist Edmund Becquerel discovered that certain materials would give off a spark of electricity when exposed to sunlight. This photoelectric effect was used in primitive solar cells made of selenium in the late 1800s. In the 1950s, scientists at Bell Labs revisited the technology and, using silicon, produced solar cells that could convert four percent of the energy in sunlight directly to electricity. Within a few years these photovoltaic (PV) cells were powering spaceships and satellites.

The most important components of a PV cell are two layers of semiconductor material generally composed of silicon crystals. On its own, crystallized silicon is not a very good conductor of electricity but when impurities are intentionally added—a process called doping—the stage is set for creating an electric current. The bottom layer of the PV cell is usually doped with boron which bonds with the silicon to facilitate a positive charge (P). The top layer is doped with phosphorus which bonds with the silicon to facilitate a negative charge (N).

The surface between the resulting "p-type" and "n-type" semiconductors is called the P-N junction. Electron movement at this surface produces an electric field that only allows electrons to flow from the p-type layer to the n-type layer.

When sunlight enters the cell its energy knocks electrons loose in both layers. Because of the opposite charges of the layers the electrons want to flow from the n-type layer to the p-type layer but the electric field at the P-N junction prevents this from happening. The presence of an external circuit, however, provides the necessary path for electrons in the n-type layer to travel to the p-type layer. Extremely thin wires running along the top of the n-type layer provide this external circuit and the electrons flowing through this circuit provide the cell's owner with a supply of electricity.

Most PV systems consist of individual square cells averaging about four inches on a side. Alone each cell generates very little power (less than two watts) so they are often grouped together as modules. Modules can then be grouped into larger panels encased in glass or plastic to provide protection from the weather and these panels, in turn, are either used as separate units or grouped into even larger arrays.

The three basic types of solar cells made from silicon are single-crystal, polycrystalline and amorphous.

-

Single-crystal cells are made in long cylinders and sliced into round or hexagonal wafers. While this process is energy-intensive and wasteful of materials, it produces the highest-efficiency cells—as high as 25 percent in some laboratory tests. Because these high-efficiency cells are more expensive they are sometimes used in combination with concentrators such as mirrors or lenses. Concentrating systems can boost efficiency to almost 30 percent. Single-crystal accounts for 29 percent of the global market for PV.

-

Polycrystalline cells are made of molten silicon cast into ingots or drawn into sheets then sliced into squares. While production costs are lower, the efficiency of the cells is lower too—around 15 percent. Because the cells are square they can be packed more closely together. Polycrystalline cells make up 62 percent of the global PV market.

-

Amorphous silicon (a-Si) is a radically different approach. Silicon is essentially sprayed onto a glass or metal surface in thin films making the whole module in one step. This approach is by far the least expensive but it results in very low efficiencies—only about five percent.

A number of exotic materials other than silicon are under development such as gallium arsenide (Ga-As), copper-indium-diselenide (CuInSe2) and cadmium-telluride (CdTe). These materials offer higher efficiencies and other interesting properties, including the ability to manufacture amorphous cells that are sensitive to different parts of the light spectrum. By stacking cells into multiple layers they can capture more of the available light. Although a-Si accounts for only five percent of the global market it appears to be the most promising for future cost reductions and growth potential.

In the 1970s, a serious effort began to produce PV panels that could provide cheaper solar power. Experimenting with new materials and production techniques, solar manufacturers cut costs for solar cells rapidly as the following graph shows.

One approach to lowering the cost of solar electric power is to increase the efficiency of cells, producing more power per dollar. The opposite approach is to decrease production costs using fewer dollars to produce the same amount of power. A third approach is lowering the costs of the rest of the system. For example, building-integrated PV (BIPV) integrates solar panels into a building's structure and earns the developer a credit for reduced construction costs.

Innovative processes and designs are continually reaching the market and helping drive down costs, including string ribbon cell production, photovoltaic roof tiles and windows with a translucent film of a-Si. Economies of scale from a booming global PV market are also helping to reduce costs.

Historically, most PV panels have been used for off-grid purposes, powering homes in remote locations, cellular phone transmitters, road signs, water pumps and millions of solar watches and calculators. Developing nations see PV as a way to avoid building long and expensive power lines to remote areas. Every year experimental solar-powered cars race across Australia and North America in heated competitions.

More recently, thanks to lower costs, strong incentives and net metering policies, the PV industry has placed more focus on home, business and utility-scale systems that are attached to the power grid. In some locations, it is less expensive for utilities to install solar panels than to upgrade the transmission and distribution system to meet new electricity demand. In 2005, for the first time ever, the installation of PV systems connected to the electric grid outpaced off-grid PV systems in the United States. As the PV market continues to expand the trend toward grid-connected applications will continue.

This distributed-generation approach provides a new model for the utilities of the future. Small generators, spread throughout a city and controlled by computers, could replace the large coal and nuclear plants that dominate the landscape now.

Source (http://www.ucsusa.org/clean_energy/our-energy-choices/renewable-energy/how-solar-energy-works.html)